R&I (remove and install) technicians are automotive experts crucial for vehicle body repair, handling tasks from part replacement to complex system reassembly. Their work's precision impacts repair outcomes, requiring deep automotive mechanics knowledge and attention to detail. Aspiring R&I pros need technical skills, interpersonal abilities, and proficiency in specialized tools and vehicle models. Practical training with real/simulated vehicles, advanced tools, and digital tutorials prepares them for safe, effective car paint services while meeting industry standards.

In today’s complex technological landscape, skilled R&I (remove and install) technicians are essential for seamless equipment maintenance and upgrades. This article delves into the critical training requirements shaping the future of this vital role. We explore the unique skills and knowledge areas needed to excel as an R&I technician, highlighting practical training methods and tools that enhance learning experiences. Understanding these key aspects ensures a competent workforce capable of addressing the evolving demands of industrial and technological advancements.

- Understanding the Role of R&I Technicians

- Essential Skills and Knowledge Areas

- Practical Training Methods and Tools

Understanding the Role of R&I Technicians

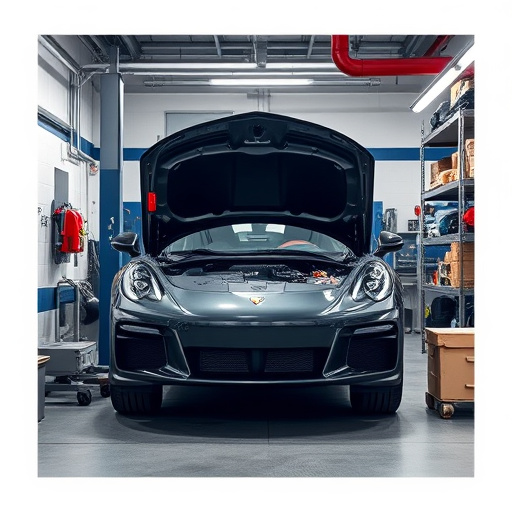

R&I (Remove and Install) technicians play a vital role in the automotive industry, specializing in crucial vehicle body repair and maintenance tasks. Their expertise lies in efficiently removing and installing various components within a car or truck’s structure, ensuring seamless integration and optimal performance. These technicians are often the first line of defence when it comes to addressing car damage repairs, as they expertly handle everything from replacing broken parts to reassembling complex systems.

Understanding the intricacies of R&I work is essential given its direct impact on automotive repair outcomes. Technicians must possess a deep knowledge of vehicle mechanics, including the ability to diagnose issues and select appropriate replacement parts. With precision and attention to detail, they navigate intricate pathways within vehicle bodies, ensuring that every removed and installed part aligns perfectly with the manufacturer’s specifications. This skill set is not just about removing and installing; it’s about fostering longevity in vehicles through meticulous R&I practices, ultimately contributing to safer and more reliable automotive repair.

Essential Skills and Knowledge Areas

For individuals pursuing a career as an R&I (remove and install) technician, a robust skill set is paramount. These professionals must possess a deep understanding of automotive mechanics, with a focus on both removal and installation processes. Essential technical skills include proficiency in using specialized tools and equipment for precise disassembly and reassembly, ensuring minimal damage during the R&I process. Knowledge of various vehicle makes and models is critical, as technicians should be adept at handling diverse car body structures, including intricate frame systems.

Beyond technical prowess, effective communication and problem-solving abilities are key assets. R&I technicians often work collaboratively within auto repair shops, requiring clear verbal and written communication to coordinate tasks. Problem-solving skills are vital when encountering unexpected issues during the removal or installation of components, demanding creative solutions for efficient troubleshooting.

Practical Training Methods and Tools

In training R&I (remove and install) technicians, practical methods are key to ensuring proficiency. Hands-on training sessions, where trainees work on real or simulated vehicles, offer an immersive experience that mirrors on-the-job challenges. This includes learning to safely remove old paint, prepare surfaces, and apply new auto body painting techniques accurately. The use of advanced tools like industrial sanders, paint strippers, and high-pressure washers is integral to these sessions, allowing technicians to familiarize themselves with equipment commonly used in auto maintenance workshops.

Interactive training materials, including digital tutorials and virtual reality simulations, also play a significant role. These tools enable trainees to practice intricate R&I tasks, such as repairing dents or replacing panels, without the risks associated with live vehicles. By combining these practical methods and cutting-edge technology, training programs equip future R&I technicians with the skills necessary to deliver exceptional car paint services while adhering to safety standards in the dynamic auto maintenance industry.

Training is key to ensuring competent R&I technicians who can efficiently navigate complex removal and installation processes. By understanding the unique demands of this role, acquiring essential skills, and employing effective training methods, organizations can empower their R&I teams to excel. Prioritizing practical, hands-on experience alongside theoretical knowledge ensures technicians are well-prepared to tackle real-world challenges in the dynamic field of R&I.