The R&I (Remove and Install) process is a crucial step in automotive repairs, including glass, dent, and paint jobs. Skilled technicians meticulously disassemble damaged components to assess and repair areas like cracked windshields, dented panels, or faded paint, ensuring precise fits. This method reduces repair times but can introduce delays due to time-intensive disassembly and reassembly. Efficient R&I execution, facilitated by structured planning, communication, and specialized tools, significantly shortens wait times, enhancing car restoration efficiency and client satisfaction.

In today’s fast-paced world, minimizing repair wait times is paramount. This article delves into the often overlooked yet significant impact of R&I (Remove and Install) processes on repair timelines. We unravel the intricacies of R&I, explore its effects on efficiency, and provide best practices to streamline these procedures. Understanding R&I is crucial for optimizing repair frameworks, ensuring faster turnaround times, and enhancing customer satisfaction. By the end, you’ll grasp how R&I strategies can revolutionize your repair management.

- Understanding R&I (Remove and Install): The Process Unveiled

- Impact on Repair Timeframes: Delays and Efficiency

- Best Practices for Minimizing R&I-Related Wait Times

Understanding R&I (Remove and Install): The Process Unveiled

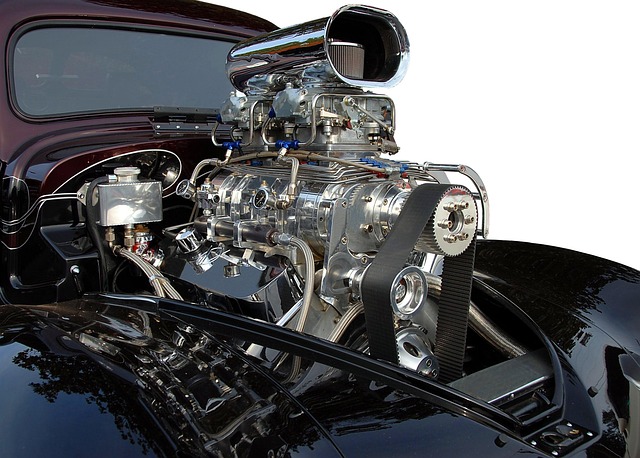

The R&I (Remove and Install) process is a fundamental step in various automotive repairs, including auto glass repair, vehicle dent repair, and car paint repair. It involves carefully disassembling damaged or faulty components from a vehicle to gain access to the affected area. This meticulous procedure requires skilled technicians who understand the intricate details of the car’s design.

By removing the compromised parts, whether it’s a cracked windshield, a dented body panel, or a faded paint job, technicians can assess the damage accurately. Once the old components are safely removed, the new replacements can be installed, ensuring a precise and secure fit. This R&I process is crucial in minimizing repair time, as it allows for efficient troubleshooting and the timely installation of necessary parts, ultimately leading to quicker turnaround times for these essential repairs.

Impact on Repair Timeframes: Delays and Efficiency

The process of R&I (Remove and Install) plays a pivotal role in shaping repair timeframes for auto body services and auto body work. This method, often employed in auto painting and other automotive restoration processes, involves meticulously disassembling damaged components before installing replacement parts or conducting repairs. While it ensures thoroughness and precision, it also introduces potential delays compared to more straightforward fixing methods.

Efficient R&I requires skilled technicians who can quickly identify and separate components without causing further damage. Delays can occur due to the time taken for disassembly and reassembly, especially in complex auto body work. However, when executed effectively, R&I can significantly enhance the quality of repairs, ensuring longevity and a seamless fit. This efficiency is crucial for auto body shops, as it not only meets customer expectations but also optimizes their operational workflow.

Best Practices for Minimizing R&I-Related Wait Times

When it comes to minimizing R&I (remove and install) wait times, a structured approach can significantly impact repair efficiency. Best practices include thorough planning and communication. Technicians should assess the scope of work before starting, ensuring they have all necessary tools and parts in advance. Clear communication with clients about expected timelines can set realistic expectations, reducing perceived delays.

Additionally, streamlining the R&I process through efficient techniques, such as using specialized tools designed for quick removal and installation, can save valuable time. In the context of auto dent repair or vehicle paint repair, these practices are especially crucial, as they directly influence the overall car restoration process, ensuring customers receive their vehicles in a timely manner.

R&I (Remove and Install) processes significantly impact repair timelines, often causing delays but also offering opportunities for efficiency gains. By understanding the intricacies of R&I and implementing best practices, organizations can minimize wait times and optimize their repair workflows. This, in turn, enhances customer satisfaction and ensures faster turnaround times, a key advantage in competitive markets.